Products technology

The reason why Sanyo Seiki is chosen

Technology

Irreplaceable : one and only technology

We have responded our customers’request from the customers’view points.

We go to the job sites and see how our products work.

We have obtained our customers’ trust making the best effort until our customers got satisfied with our products.

This designing capability makes SANYO well known in the world market as well as domestic market.

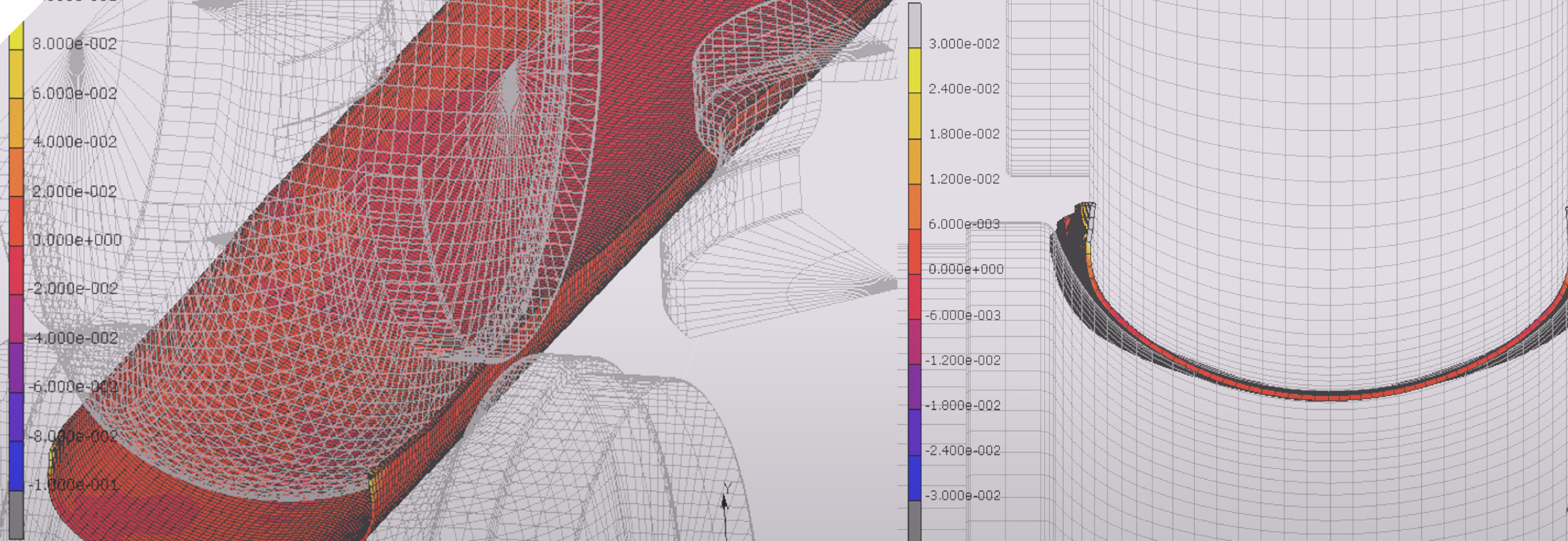

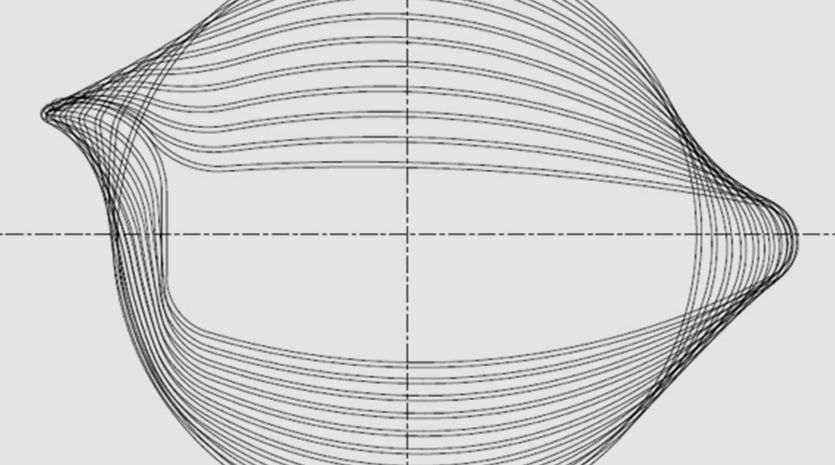

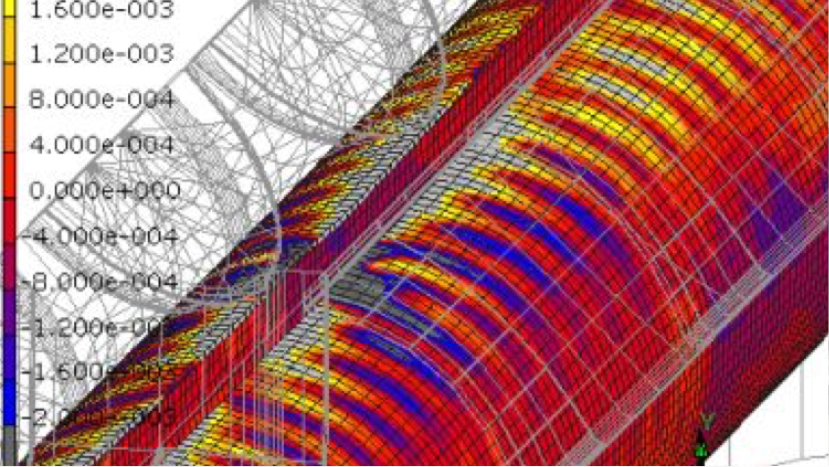

SRS: Sanyo Roll-forming Simulation

In 2007, our engineering division started roll forming analysis using “Finite Elemental Method”.

Inputting data of the material specifications and roll-shapes the analysis software analyzes the forming visually. It makes us see the validity of roll forming without actual production.

Having this detailed analysis makes it possible to respond customers’ technical needs.

Quality

With the pride of “Made in Japan”, we sell our rolls to the world.

We have a thorough quality control. We use a scheduler and a bar code reader to produce rolls smoothly.

With those help anybody will be able to see the process of roll forming.

We also check the quality of finished products and packaging.

Solutions

To meet various demands of the customers, we have several services.

- We have plenty of special steel raw materials in stock. It makes us possible to meet customers’ urgent delivery request.

- We are able to accept small orders like a few kilos and a big order (more than 100 tons).

- Each branch sales office has belonged their own engineering staff. We, therefore, are able to respond customers’ troubles immediately.

- We have a lot of experience of providing roll maintenance and set-up rolls at customer’s sites.

If you have questions or want to make an inquiry, press the button “Inquiry”